Home | About us

About us

Project

Coordinator

Susana Camarero

E-mail: susanacam@cib.csic.es

Phone: +34 918373112

Biological Research Centre (CIB)

Calle Ramiro de Maeztu 9, E-28040 Madrid, Spain

Susana Camarero is Tenured Scientist of CSIC in the group of Biotechnology

for Lignocellulosic Biomass of the Microbial and Plant Biotechnology Department, at the CIB. She has

more than 75 publications, mainly related to ligninolytic oxidoreductases and microbial biotechnology.

She has participated in more than 30 national and international research projects, including ten

European projects (FP3-FP7 and H2020), a cooperation project with Colombia (as coordinator) and a

collaborative project of US JGI-DOE. Since 2011, she coordinates the Spanish Thematic Network of

Biotechnology applied to Lignocelluloses (www.redlignocel.es).

The WoodZymes consortium covers the whole value chain from research to end-users which will ensure rapid uptake and exploitation of the project results. With this purpose it brings together one SME (MetGen) specialized in the designing, production and supply of industrial enzymes for biomass conversion, three research groups with high expertise on lignin biodegradation and oxidoreductases (CIB), extremophilic hydrolases (IATA) and chemical analysis of lignin and lignocellulosic materials (IRNAS); three technological centres dedicated to developing more sustainable and cleaner processes for the pulp and paper industry (CTP, RAIZ) or the forest(wood)-based sector (FCBA); as well as four world-leading companies in the sectors of bleached eucalypt kraft pulp and printing paper (Navigator), softwood kraft pulp (FibEx), fibreboards (FINSA) and insulation materials (Soprema).

The CIB contribution to WoodZymes is led by Dr Susana Camarero, CSIC Tenured Scientist with large experience in laccase ad

laccase-mediator systems (directed evolution and applications), who is also the Project Coordinator. She will be supported by

Prof Ángel T. Martínez, expert in oxidoreductases and microbial biotechnology who has coordinated seven EU projects, Dr Marta Pérez-Boada,

Project Manager in charge of the Project Secretariat (see Contact section) and Dr Francisco J. Ruiz-Dueñas, expert in heme peroxidases

(molecular biology, structure-function and engineering). Dr Alicia Prieto and Prof Mª Jesús Martínez are also involved in the project.

The CIB contribution to WoodZymes is led by Dr Susana Camarero, CSIC Tenured Scientist with large experience in laccase ad

laccase-mediator systems (directed evolution and applications), who is also the Project Coordinator. She will be supported by

Prof Ángel T. Martínez, expert in oxidoreductases and microbial biotechnology who has coordinated seven EU projects, Dr Marta Pérez-Boada,

Project Manager in charge of the Project Secretariat (see Contact section) and Dr Francisco J. Ruiz-Dueñas, expert in heme peroxidases

(molecular biology, structure-function and engineering). Dr Alicia Prieto and Prof Mª Jesús Martínez are also involved in the project.

The contribution of IRNAS to WoodZymes will be led by Dr. Ana Gutiérrez, CSIC Research Scientist, current

Vice-director of IRNAS, recent elected member (2015) of the International Academy of Wood Science (IAWS) (2015)

and of IAWS Academy board (2016), who has ~150 SCI articles (and several patents) mainly related to lignocellulose

chemistry and enzymatic modification of plant lipids and lignin. She has participated in the coordination of 6 EU

projects, and has been the responsible of several EU and National projects. Other members of the group are Prof.

José C. del Río, Dr. Jorge Rencoret, Dr. Gisela Marques, Dr. Alejandro González, Dr.

Esteban D. Babot, Andrés Olmedo and Carmen Aranda.

The contribution of IRNAS to WoodZymes will be led by Dr. Ana Gutiérrez, CSIC Research Scientist, current

Vice-director of IRNAS, recent elected member (2015) of the International Academy of Wood Science (IAWS) (2015)

and of IAWS Academy board (2016), who has ~150 SCI articles (and several patents) mainly related to lignocellulose

chemistry and enzymatic modification of plant lipids and lignin. She has participated in the coordination of 6 EU

projects, and has been the responsible of several EU and National projects. Other members of the group are Prof.

José C. del Río, Dr. Jorge Rencoret, Dr. Gisela Marques, Dr. Alejandro González, Dr.

Esteban D. Babot, Andrés Olmedo and Carmen Aranda.

CTP’s participation in WoodZymes is led by Dr Michel Petit-Conil, who has large experience in enzyme application in mechanical and chemical

pulping, pulp bleaching and chemical pulp refining. Dr Valérie Meyer and Dr Auphélia Burnet, senior scientists in lignocellulosic chemical

pulping and bleaching, are also involved in the project.

CTP’s participation in WoodZymes is led by Dr Michel Petit-Conil, who has large experience in enzyme application in mechanical and chemical

pulping, pulp bleaching and chemical pulp refining. Dr Valérie Meyer and Dr Auphélia Burnet, senior scientists in lignocellulosic chemical

pulping and bleaching, are also involved in the project.

FCBA InTechFibres team will be in charge of lab and pilot board production to evaluate the effect of enzyme addition at different stages of

the process. The environmental and socio-economic assessment will be managed by the Environment, Economy and Bio-Resources Department at FCBA,

with large expertise in the field of environmental and economic performance of wood transformation processes. FCBA will also contribute

to project management (being work package co-leader) and dissemination.

FCBA InTechFibres team will be in charge of lab and pilot board production to evaluate the effect of enzyme addition at different stages of

the process. The environmental and socio-economic assessment will be managed by the Environment, Economy and Bio-Resources Department at FCBA,

with large expertise in the field of environmental and economic performance of wood transformation processes. FCBA will also contribute

to project management (being work package co-leader) and dissemination.

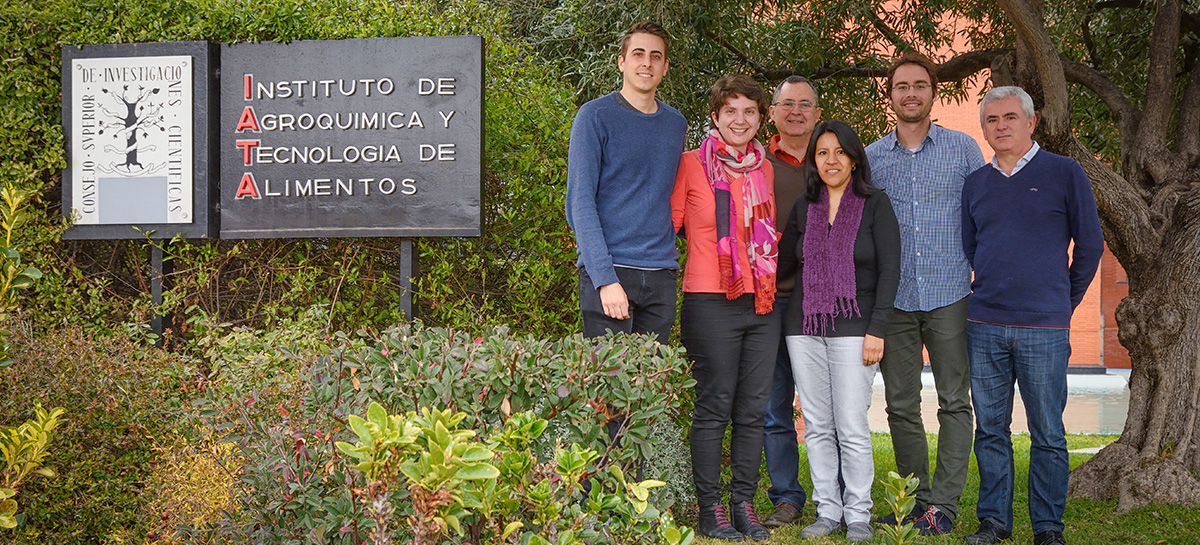

The group members involved in WoodZymes are Dr Julio Polaina, CSIC Research Scientist leading the Laboratory since 1995,

Dr Julia Marín-Navarro, expert in protein biochemistry, and Dr David Talens-Perales, expert in microbial biotechnology,

enzymology and bioinformatics.

The group members involved in WoodZymes are Dr Julio Polaina, CSIC Research Scientist leading the Laboratory since 1995,

Dr Julia Marín-Navarro, expert in protein biochemistry, and Dr David Talens-Perales, expert in microbial biotechnology,

enzymology and bioinformatics.

MetGen’s CEO (Alex Michine), CTO (Matti Heikkilä) and R&D Director (Klara Birikh) are involved in the project,

together with the EU project manager (Petri Ihalainen) and several staff scientists (Veera Hämäläinen, Antoine Mialon,

Toni Grönroos, Anu Suonpää and Bastiaan Romein) with expertise in biotechnology applications, genetic and protein

engineering and fermentation technologies.

MetGen’s CEO (Alex Michine), CTO (Matti Heikkilä) and R&D Director (Klara Birikh) are involved in the project,

together with the EU project manager (Petri Ihalainen) and several staff scientists (Veera Hämäläinen, Antoine Mialon,

Toni Grönroos, Anu Suonpää and Bastiaan Romein) with expertise in biotechnology applications, genetic and protein

engineering and fermentation technologies.

Participation in WoodZymes is coordinated by Dr Paula Pinto, R&D Coordinator with more than 15 years experience as

researcher in biorefinery projects. Other members involved in the project are Fernando Martins,

M. Manuela Marques and Rui Pedro Pereira.

Participation in WoodZymes is coordinated by Dr Paula Pinto, R&D Coordinator with more than 15 years experience as

researcher in biorefinery projects. Other members involved in the project are Fernando Martins,

M. Manuela Marques and Rui Pedro Pereira.

Leonor Guedes, Environmental Engineer with more than 30 years experience in pulp and paper research is responsible for RAIZ

participation in WoodZymes. Senior scientists Luís Machado and António Mendes de Sousa, Environmental and Chemical Engineers,

respectively, are also involved in the project.

Leonor Guedes, Environmental Engineer with more than 30 years experience in pulp and paper research is responsible for RAIZ

participation in WoodZymes. Senior scientists Luís Machado and António Mendes de Sousa, Environmental and Chemical Engineers,

respectively, are also involved in the project.

Participation in the project is led by R&D Manger Rémi Perrin, Engineer in material science with more than 20 years of experience

in the R&D department management. Dr Stéphanie Laurichesse (expert in lignin applications), Dr Alexandru Sarbu

(in charge of PU foam formulation), Dr Jérémie Boucher (R&D manager for wood fibre insulation activities) and Sarah Mennuni

(lab technician) are also involved.

Participation in the project is led by R&D Manger Rémi Perrin, Engineer in material science with more than 20 years of experience

in the R&D department management. Dr Stéphanie Laurichesse (expert in lignin applications), Dr Alexandru Sarbu

(in charge of PU foam formulation), Dr Jérémie Boucher (R&D manager for wood fibre insulation activities) and Sarah Mennuni

(lab technician) are also involved.